NDT is the preferred choice amongst engineers across various industries. The biggest advantage of NDT is that it does not alter the material being tested and thus it is a very valuable technique to save time and money in product evaluation, testing and trouble shooting.

For many years, Ashraf Industrial Products Division has been the leading supplier in Kuwait for various globally acclaimed solutions in this field. Our expertise lies in the following areas:

X-ray Products

YXLON International is the leading provider of X-ray inspection equipment for industrial applications. Whether operated manually, semi-automatically or on a fully automatic scale, we have the right solution to match nearly every application. For us, the highest priority is placed on quality: the quality of our inspection systems and, as a result, the quality of your products. Our years of experience and the pleasure we take in innovation have enabled us to gain the confidence and trust of the most renowned manufacturers in the automotive industry, aviation and aerospace, shipbuilding and vessel construction, electronics and other industrial sectors.

Mobile X-ray machines

Mobile X-ray generators from YXLON International are designed to supply very high power in areas with limited space or access. For instance, these generators are perfectly designed for operations at nuclear power plants and in the petrochemical industry. All components are carried on a trolley equipped with positions for tilting and a hook for lifting via crane. The mobile system’s high-voltage cable is additionally shielded in order to secure safe operation for your company and a long product lifetime.

Portable X-ray machines

Portable X-ray generators from YXLON International are designed and manufactured to offer the most reliable and efficient services under the toughest working conditions anywhere on the globe. These generators are based on more than 50 years of experience and excellence in the field. Today they offer user-friendly and intuitive operating menus that enable maximum in-the-field productivity. YXLON portable generators provide for extremely stable X-ray output and are insensitive to irregularities in the power supply. Their power consumption is extremely low, so your operations leave a green footprint behind, worldwide. By the same token, operational time can be reduced as well, leading you to significant savings in costs, energy and operations. The portable X-ray generators and control units are designed to excel in rugged environments, whether at high or low temperatures. No matter how tough the conditions, YXLON portable X-ray generators are designed to withstand dust and water and are extremely well suited for crawler applications, too.

Stationary X-ray machines

Highly stable and robust constant-voltage X-ray generators from YXLON form the basis for non-destructive testing by means of X-rays.

- High voltage from 100 kV to 600 kV

- Output-optimized focal spot through Variofocus technology

- Stable, constant voltage power supply

- Robust, even in the event of tube malfunctions

Stationary universal constant-voltage X-ray generators from YXLON with a power output of up to 4.5 kW and high voltages of up to 600 kV are utilized in a large number of applications.

The stationary X-ray generators were designed for operation in radioscopic inspection systems and for radiography. Moreover, their high stability and setting precision for both the high voltage and tube current make these X-ray generators very well suited for the use in computed tomography and dosimetry.

The X-ray generators are supplemented by a large selection of accessories, including motorized or manual collimators, tripods or X-ray beam cantering aids.

CT Systems

Y.MU2000-D – High-quality inspection in spot-check sample and series inspection now also available with CT option

Y.MU2000-D is a solution that has proven itself on the market. Equipped with modern digital flat-panel detectors and Y.HDR-Inspect technology, it provides brilliant image quality displaying a high contrast and can also be upgraded with computed tomography now.

- Robust and proven technology

- In use worldwide with over 490 systems

- Highly dynamic radioscopy (HDR)

- Manual and programmable inspection

- NEW! Fast computed tomography at the touch of a button

Using Y.HDR-Inspect, scanning inspection involving digital “highly dynamic radioscopy”, the inspection item is inspected in motion by employing a combination of a flat-panel detector and Y.IMAGE image processing. Extremely brilliant images displaying a three-dimensional character for detailed analysis are the result (for more information, please look at Technologies – Y.HDR-Inspect as well).

Parallel to its irradiation function, Y.MU2000-D is optionally equipped with computed tomography to provide the user with even more detailed information on the location and area of casting flaws.

Y.MU2000-D can be deployed equally well for both spot-check sample and series inspection. The system offers high-grade material inspection quality, even when the materials are as different as steel, aluminium, ceramics, plastic or rubber

Pipeline Crawlers

JME is regarded across the globe as the market leader for the development and manufacture of high quality inspection systems. JME are very proud to have supplied the industry over the past 35 years, with a client base that is growing by the day. Innovation, Quality, Service and Commitment to the industry are JME’s objectives, over the past 35 years this is what JME has built its reputation on. JME manufacture the world renowned JME Pipeline Crawler inspection system, Betatron Portable X-Ray systems and Digital X-Ray inspection systems.

JME DXB:1 DIGITAL X-RAY BUGGY

SINGLE WALL SINGLE IMAGE (SWSI) + DOUBLE WALL SINGLE IMAGE (DWSI) OPERATION

DXB:1 Digital X-Ray Buggy; designed to produce high-quality panoramic digital radiographs of circumferential welds in applications such as new pipelines. As a versatile and configurable system, it can also be utilised for use in various non-pipeline applications, such as the inspection of tank walls or other ferrous metal structures.

This digital system is a replacement for traditional film radiography; so no more chemical processing, dark rooms, or flaws associated with conventional radiography. The DXB includes a high-definition digital panel for instant verification of image quality and system settings. Images are digitally stored, preventing the need for film storage and enabling a permanent record to be saved within the control tablet. These can be backed up via USB or using a Network connection, allowing the images to be sent to an off-site Radiographer seconds from acquisition.

JME’s DXB system also communicates and integrates with our entire CR2 Pipeline Crawler Range. This allows 2-way communication between the Pipeline Crawler and DXB, giving configuration of key crawler parameters from the DXB control tablet. This integration also allows commencement of inspection with the push of a single button. The DXB operator is able to control, adjust and view the status of the CR2 crawler at all times during an inspection task.

JME 6:CR1 PIPELINE CRAWLER

JME’s 6:CR1 pipeline crawler is specifically designed for non-destructive testing (NDT) of circumferential butt welds in tubular installations such as oil and gas transmission pipelines.

The JME 6:CR1 Pipeline Crawler is extremely compact and lightweight. It enables the operator to produce internal panoramic single wall single image (SWSI) radiographs. This is a versatile system and will operate in pipleines down to 5.3” (135mm) and up to a maximum of 18” in diameter.

The JME 6:CR1 crawler is powered by high-efficiency rechargeable sealed lead acid batteries. The crawler can be commanded either using JME’s magnetic control system (Magnetope) or alternatively with a conventional isotope control system. These systems can be used to control travel, park and exposure modes from outside the pipeline.

Safety and asset protection are always a consideration. The JME 6:CR1 crawler features anti-runaway circuitry along with optional audio/visual alarm unit and purpose built latching recovery vehicle.

JME 6:CR2 PIPELINE CRAWLER

The JME 6:CR2 Pipeline Crawler is specifically designed for non-destructive testing of circumferential butt welds in tubular installations such as oil and gas transmission pipelines.

Our 2nd Generation CR2 range is the world’s most ‘Technologically Advanced’ NDT crawler system. The JME 6:CR2 Pipeline Crawler is extremely compact and lightweight, deployable in an Internal Diameter (ID) range between 5.5” (140mm) and a maximum of 18” (457mm). Coupled with X-Ray generators from JME or ICM, this system can produce internal panoramic single-wall-single-image (SWSI) radiographs of very high quality.

The crawler can be commanded using JME’s Magnetic Control System (Magnetope), or a conventional isotope control system, additional features are accessible using our brand new CR2 Remote Handset.

JME 10:CR2 PIPELINE CRAWLER

The JME 10:CR2 Pipeline Crawler is specifically designed for (NDT) non-destructive examinations of circumferential butt welds in tubular installations such as oil and gas transmission pipelines, while in construction.

The JME 10:CR2 Pipeline Crawler is capable of driving a wide range of X-Ray generators and gamma head / actuator units, enabling internal panoramic Single Wall Single Image (SWSI) radiography to be carried out in pipe diameters from 10″-48″.

Constructed using high grade materials to provide a good finish, superior corrosion resistance, easy maintenance and extended service life. Electronic circuitry utilising military specification components, ensuring reliability in harsh environments. Powered by high-efficiency rechargeable sealed lead acid batteries.

Full remote control of travel, park and exposure modes from outside the pipeline using the JME ‘Magnetope’ or a low activity isotope. Safety features include anti-runaway circuitry, and optional retrieval latching purpose built recovery vehicle and an automatic radio recovery system.

JME 24:CR2 PIPELINE CRAWLER

JME’s 24:CR2 Pipeline Crawler is specifically designed for non-destructive testing of circumferential butt welds in tubular installations such as oil and gas transmission pipelines.

Our 2nd Generation CR2 range is the world’s most ‘Technologically Advanced’ NDT crawler system. The JME 24:CR2 Pipeline Crawler is robust and suitable for use in a wide range of challenging environmental conditions. Deployable in an Internal Diameter (ID) range between 22″ (558mm) and a maximum of 60″ (1524mm). Coupled with X-Ray generators from Balteau, Yxlon and ICM, this system can produce internal panoramic single-wall-single-image (SWSI) radiographs of very high quality.

The crawler can be commanded using JME’s Magnetic Control System (Magnetope), or a conventional isotope control system, additional features are accessible using our brand new CR2 Remote Handset.

JME 12:CR2 GAMMA CRAWLER

JME are proud to offer its Gamma Pipeline Solution for customers using this technology for their radiographic butt weld inspection. This solution is suitable for the inspection of circumferential butt welds in new build pipelines with a diameter from 12” to 48”. This product offers the precision engineering and reliability that JME are renowned for, integrating with both the SENTINEL Delta 880 or Oserix Dual 120 gamma projectors.

With its exceptional build quality, reliability and dealer network, combining the gamma head with JME’s crawler chassis gives users the confidence to take on any inspection task. Our complete Gamma pipeline solution will be delivered ready for loading with an appropriate source, this is supplied locally and can be reloaded as required using service centers. The coupling mechanism for the Projector is designed to be simple to use, making it very easy to remove the unit for secure overnight storage.

Ultrasonic Products

Olympus provides an industry-leading portfolio of innovative test, measurement, and imaging instruments.

Leading edge testing technologies include remote visual inspection, ultrasound, phased array, eddy current, eddy current array, X-ray fluorescence and diffraction. Our products include ultrasonic flaw detectors and thickness gages, videoscopes, borescopes, in-line and advanced non-destructive testing systems, XRF and XRD analyzers, interferometers, and a large selection of industrial scanners, probes, software programs, and instrument accessories.

Olympus instruments are used in industrial and research applications ranging from aerospace, power generation, petrochemical, manufacturing, and automotive to consumer products. Olympus instruments contribute to the quality of products and add to the safety of infrastructure and facilities.

Ultrasonic Flaw detectors and Thickness Gages.

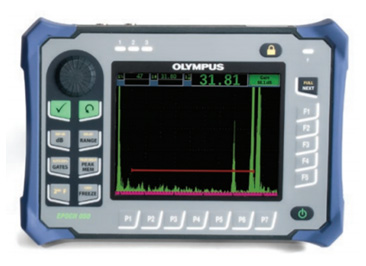

EPOCH 650 Digital Ultrasonic Flaw Detector

The large, full VGA transflective display combined with our patented digital high dynamic range receiver provides a stable, striking A-scan representation in any lighting condition. The EPOCH 650 is designed to meet the requirements of EN12668 1 and allows a full range of standard and optional flaw detection features.

The EPOCH 650 Digital Ultrasonic Flaw Detector combines Olympus’ industry leading conventional flaw detection capabilities with the efficiency of a highly portable, intuitive instrument. The EPOCH 650 flaw detector’s blend of efficient menus and direct access keys allows you to take advantage of the highest quality flaw detection platform with exceptional ease of use.

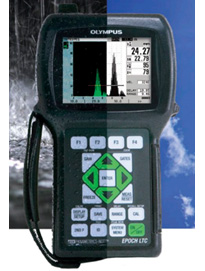

EPOCH LTC: Rugged Handheld Flaw Detector

The EPOCH LTC is a mid-level, handheld ultrasonic flaw detector in a compact 2.12 lbs (0.96 kg) vertical case. It is a full-featured instrument with EN12668-1 compliance and a wide variety of standard features as well as specialized options to meet your inspection needs.

The EPOCH LTC Digital Ultrasonic Flaw Detector offers state-of-the-art technology in a package that is compact and lightweight 2.12 lbs (0.96 kg). Based on the design of the class-leading EPOCH XT, the EPOCH LTC is a full-featured instrument with EN12668-1 compliance and a wide variety of standard features as well as specialized options to meet your inspection needs.

27MG ultrasonic thickness gage

The Olympus 27MG is an affordable ultrasonic thickness gage designed to make accurate, measurements from one side on internally corroded or eroded metal pipes, tanks, and other equipment. It weighs only 12 oz. (340 g) and is ergonomically designed for easy, one-hand operation.

Standard features include Automatic Probe Recognition to ensure optimal transducer performance, Auto Zero compensation to enhance the accuracy of measurements on hot surfaces, Gain Adjust to improve measurements on sound-attenuating materials such as cast metals, Differential mode, Hi-Low Alarm settings, and a Min./Max. mode that captures the minimum or maximum thickness at 20 measurements per second.

45MG Ultrasonic Thickness Gage: Simple Operation, Rugged, and Reliable

The 45MG is an advanced ultrasonic thickness gage packed with standard measurement features and software options. This unique instrument is compatible with the complete range of Olympus dual element and single element thickness gage transducers, making this innovative instrument an all-in-one solution for virtually every thickness gage application.

38DL PLUS Ultrasonic Thickness Gage

The 38DL PLUS is an innovative instrument that signals a new era in ultrasonic thickness gaging. Ideally suited for almost every ultrasonic thickness application, this handheld thickness gage is fully compatible with a full line of dual and single element transducers.

Advanced Ultrasonic System

OmniScan MX2 Phased array system

The result of over 10 years of proven leadership in modular NDT test platforms, the OmniScan MX has been the most successful portable and modular phased array test instrument produced by Olympus to date, with thousands of units in use throughout the world.

Olympus now offers a new PA module with TOFD, a new UT module, as well as new software programs (NDT Setup Builder and new OmniPC version) that expand the capabilities of the successful OmniScan MX2 platform and improve the workflow efficiency of non-destructive testing inspections.

This second generation OmniScan MX2 increases testing efficiency, ensuring superior, advanced AUT application performance with faster setups, test cycles, and reporting, in addition to universal compatibility with more than 10 phased array and ultrasound modules. Designed for NDT experts, this high-end, scalable platform delivers true next-generation NDT performance.

The OmniScan MX2 offers a high acquisition rate and new powerful software features for efficient manual and automated inspection performance—all in a portable, modular instrument.

OmniScan SX Phased array system

Olympus is proud to introduce the OmniScan® SX, a flaw detector that benefits from more than 20 years of phased array experience and shares the OmniScan DNA. For improved ease of use, the OmniScan SX features a new streamlined software interface displayed on an 8.4 in. (21.3 cm) touch screen. A single-group and non-modular instrument, the OmniScan SX is easy to operate and cost-effective for less demanding applications.

The OmniScan SX comes in two models: the SX PA and SX UT. The SX PA is a 16:64PR phased array unit, which, like the UT-only SX UT, is equipped with a conventional UT channel for pulse-echo, pitch-catch or TOFD inspection. Compared to the OmniScan MX2, the SX is 33% lighter and 50% smaller, offering an unprecedented level of portability for an OmniScan.

EPOCH 1000 Series

The EPOCH 1000 is an advanced conventional ultrasonic flaw detector that can be upgraded with phased array imaging at an authorized Olympus service center. Key features include: EN12668-1 compliant, 37 digital receiver filter selections, and 6 kHz pulse repetition rate for high speed scanning.

Eddy Current and Eddy Current Array Products

NORTEC 600 Eddy Current Flaw Detector

Olympus converges its latest advancements in high-performance digital circuitry and eddy current flaw detection into one compact and durable portable unit—the new NORTEC® 600. With its crisp and vivid 5.7 inch VGA display and true full-screen mode, the NORTEC 600 is capable of producing highly visible and contrasting eddy current signals in any lighting condition.

MultiScan MS5800 Instrument

The MultiScan MS5800 is a multi-technology system offering these technologies:

- Eddy Current

- Magnetic Flux Leakage

- Remote Field

- IRIS Ultrasound

- Tube Inspection with Eddy Current Testing (ECT)

- Tube Inspection with Internal Rotating Inspection System (IRIS) for Ferrous and Nonferrous Materials

- Tube Inspection with Remote Field Testing (RFT)

- Tube Inspection with Near Field Testing (NFT)

- Tube Inspection with Magnetic Flux Leakage (MFL)

The OmniScan MX ECA/ECT

With thousands of units being used throughout the world, the OmniScan® MX is a field-proven, reliable instrument that is built to withstand harsh and demanding inspection conditions. Compact and lightweight, its two Li-ion batteries provide up to 6 hours of manual or semi-automated inspection time.

Remote Visual Testing Products.

IPLEX NX Industrial Videoscopes

The IPLEX NX brings you the most advanced technologies in IPLEX series. It provides a bright, high-resolution image even in large spaces through a high-quality image sensor, bright laser diode light source, high-level image processing technology, and Olympus’s optical lens technology.

The IPLEX NX is engineered to deliver high-resolution images. Its reliable image quality enables users to clearly identify trouble spots and defective areas, so inspectors can make correct judgments about crucial systems and technologies.

IPLEX RX/RT Industrial Videoscopes

The IPLEX RX/ IPLEX RT are lightweight industrial videoscopes that feature the unique PulsarPic image processor to produce exceptionally high-resolution and bright images. They have a large 6.5-inch screen with an anti-reflective daylight-view monitor.

XRF Analysers

The Vanta Series: Rugged. Revolutionary. Productive handheld XRF analyzers

The Vanta analyzer is our most advanced handheld X-ray fluorescence (XRF) device and provides rapid, accurate element analysis and alloy identification to customers who demand laboratory-quality results in the field.

The DELTA Series

Everything You Need in Handheld XRF with State-of-the-Art Innovation

The DELTA handheld XRF analyzers are ergonomically advanced with a forward looking design incorporating the latest in electronics, components, and software technology. The DELTA X-act Count technology can provide even better sensitivity and precision in faster time for more materials than before. Throughput is increased with the same or better precision in half the time for most elements.

Digital Imaging Products

Carestream Health (CSH) is a dynamic global company with over 100 years of leadership. They are passionately committed to doing whatever it takes to help our customers be successful. It’s that simple and that clear.

Carestream serve customers in the following market segments: Radiography and Healthcare IT , Dental imaging and practice management software , Non-destructive testing, Tollcoating & Advanced Materials.

NON-DESTRUCTIVE TESTING (NDT)

CSH NDT solutions address the unique needs of aerospace, petrochemical and other industrial testing with innovative research, products and services. Our development teams continually work to make sure our NDT products can perform radiographic testing (RT) anywhere in the world.

Carestream INDUSTREX HPX-PRO Digital System

CR for Anywhere NDT Takes You

The HPX-PRO Portable CR System is designed for high throughput digital imaging in rugged NDT environments. It’s a lightweight (35lbs/16Kg), portable solution that can be set-up in less than 5 minutes and process a weld in up to a minute, producing high-quality digital images for quick analysis and rapid final reporting. HPX-PRO is a complete solution using Carestream’s INDUSTREX software to scan, display and store your all your digital data.

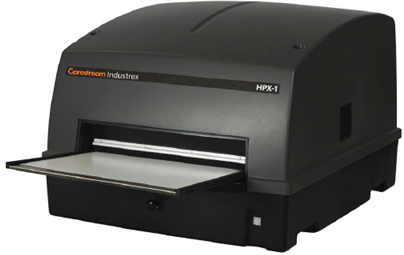

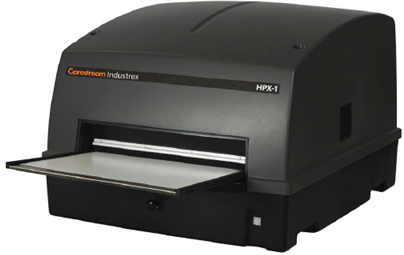

Carestream INDUSTREX HPX-1 Digital System

The future of NDT has arrived. Built from the ground up to meet the varied and specific needs of rigorous non-destructive testing applications, only the HPX-1 has the capability to handle long plates, short plates, rigid cassettes and flexible plates—all in a single system.

With industry leading image resolution: the HPX-1 delivers weld-quality images, consistently and dependably, as well as full dynamic range and sensitivity for all other applications.

INDUSTREX X-ray Films & Chemicals.

Providing outstanding quality and consistency. We offer a variety of film solutions to satisfy your non-destructive testing needs—suitable for any exposure method—with film processors that provide outstanding quality and consistency.

We also offer quality tools for detection and measurement of radiation exposure, designed to help you measure more accurately, monitor your process and add value to your images.

NDT X-RAY FILM PROCESSORS

Energy-Saving, Powerful NDT Processors. Meet two powerful innovations for producing high-quality NDT Radiographs. Choose the INDUSTREX M43IC for high-volume output or the INDUSTRX M37 for space-saving design and mid-volume output.

Gamma Radiography Products

NTP Europe is a leading producer and supplier of quality sealed sources and related equipment for the industrial and medical sectors. Strategically situated in Fleurus, Belgium, the company is committed to providing a reliable and sustainable supply of excellent products and services, strongly supported by the renowned competence of its parent company, NTP Radioisotopes (based in South Africa).

The Company serves mission-critical industries where products are utilised for a wide range of applications from the verification of the integrity of components from pipelines to aircraft engines and critical components, including bridges and offshore platforms, to brachytherapy in the medical sector.

Radioactive Sealed Sources

TP Europe has specialised in the fabrication of radioactive sealed sources for more than 30 years and offers loading and unloading of a large variety of devices and services allowing customers to have a full suite of support.

All sources are tested for leakage and contamination using our activity measurement chambers that have been calibrated by an official and independent body. They are regularly controlled by means of calibrated sources.

All NTP Europe sealed sources conform to the International Standard Organisation recommendations ISO 2919:1999 (test performed by the Laboratoire National d’Essais – Trappes – France) and the French NFM 61-002:1984 (AFNOR) standards.

Equipment

For over 30 years, GammaMat has been internationally trusted and recognised as a pioneer in the development of gamma radiography equipment. Its reliability and ease of operation has contributed in the establishment of the highest safety norms and standards.

The equipment NTPE supply includes:

- GammaMat TSI/1 (Ir-192 lightweight gamma ray projector)

- GammaMat SE (Highly portable Se-75 gamma ray projector)

- GammaMat M (Self-propelled isotope crawler for pipeline radiography)

Optical Emission Spectrometers.

The Belec Spektrometrie Opto-Elektronik GmbH is a medium-sized company with its place of business in Georgsmarienhütte near Osnabrück, where more than 40 years ago, an idea was born.Today, Belec develops, produces and distributes mobile and stationary optical emission spectrometers for metal analysis worldwide.

Founded in 1986, Belec operates at home and abroad for more than 25 years now.

Our products are used in various fields like the steel industry, foundries and recycling companies or the automotive industry.

Belec Compact Port HLC

The Belec Compact Port HLC is the World’s only Portable Hybrid Spectrometer for Metal Analysis For perfect Analysis of Carbon combined with Best and Unique Flexibility and latest 6GSO-System.

Flexibility combined with best possible precision: By using the latest digital detectors (CCD) which cover the entire spectral range for consequent line selection without compromises, plus high performing Photomultipliers for selected elements like Carbon that guarantee lowest detection limits and unattained performance.

Destructive Material Testing Products

Shimadzu provides a broad range of analytical instruments indispensable for research, development, and quality control in a variety of fields. Our high-level, sophisticated instruments include chromatographs, spectrometers, and elemental and surface analysis systems. We also provide a broad range of high-precision physical testing and measuring technology that is essential for product development and quality assurance.

Universal Testing

Shimadzu offers a range of first-class testing instruments to meet R&D requirements in the development of safer and higher quality materials and products. With Universal/Tensile Testers like the AG-X plus Series, AGS-X Series and the Table-top EZ Test Series, Capillary Flow and Endurance Testers, and a variety of Micro Hardness Testers like the DUH-211 Series, the choice is yours. Combined with Shimadzu’s selection of accessories, including grips, extensometers, and jigs, and the optional Windows®-compatible Trapezium Software, which provides simplified user operation with Wizards and the industry’s premier navigation system, Shimadzu can provide you with a solution for any environment or application.

Hardness Testing

Shimadzu’s range of hardness testers – including conventional JIS-compatible models and models utilizing new principles of operation – can evaluate the hardness (strength) of all materials from steel through to new materials and from micro parts through to large products.

Fatigue Testing

With improved reliability and safety called for as a result of environment problems and in electronic and transportation equipment, R&D is being conducted vigorously into high-performance, high-reliability materials and products. For this reason, the methods for evaluating the strength properties and reliability of these materials and products also have become advanced and complex. The Shimadzu Servopulser provides you with the functions for building a system that can flexibly and optimally accommodate various evaluations and tests of this kind.

MFL Inspection Products

Founded in 1994 by Bill Duke, MFE Enterprises is a family owned and operated MFL inspection equipment provider that takes great pride in helping its customers all over the world find the right tool for the job. MFE Enterprises manufactures Non-Destructive Testing (NDT) and Magnetic Flux Leakage (MFL) inspection equipment for both storage tank and pipeline applications. MFE designs equipment for fast and accurate inspections of your plant assets with cutting edge, lightweight equipment such as the 65 lb Mark IV Tank Floor Scanner and 61lb MFE Edge. All MFE Enterprises inspection equipment is maintained by highly experienced specialists with an extensive industry-specific knowledge base. MFE Enterprises will ensure you get the right equipment for your specific application delivered on time, and in the proper condition, so that your inspection is fast, accurate, and cost-effective.

Mark IV Tank Scanner

The Mark IV takes the precision, reliability, and durability of its predecessors to another level with state-of-the-art, user-friendly software and a lightweight build. Its slim design boasts an unprecedented weight of only 65 lb. Operators are able to discover volume loss in real time with its true real-time display and switch to a mapping mode with the touch of a button. A carbon fiber body, military-spec breakaway cables, and the ability to conveniently separate and store the Mark IV into two separate custom cases ensure the Mark IV is durable, easily transportable, reliable, and unrivaled.

MFE EDGE (MFL Edge Scanner)

The MFE Edge is the new 61 lb Mark IV Edge Scanner from MFE Enterprises and features both manual and mapping modes. The MFE EDGE can work alone as an edge scanner and a full tank floor scanner, or it can work seamlessly with the Mark IV Tank Scanner, allowing operators to import MFE EDGE reports into the Mark IV to create one comprehensive analytical report.

MFE PIPESCAN (MFL Pipe scanner)

The MFL pipe scanner can inspect pipes with a diameter of 5” and up at a speed of up to 3 feet per second. PipeScan is capable of scanning through thin coatings to detect water, fuel and chemical leaks. View digital volume loss signals in real-time on the included Getac Tablet display.

Penetrant and Magnetic particle Inspection Products

Established in the year 2003, MR Chemie India Pvt. Ltd. (a joint-venture unit of MR Chemie GmbH, Germany) has been well-known as an expert manufacturers and suppliers of Dye-Penetrant, Magnetic Particle Inspection consumable and accessories, Leak Detection, UV-Technology, Special Chemicals and more. Our company has grown substantially, increasing its share of the international market many times over. The products of our company are used in industrial, commercial and many more applications. The products we offer to the customers are quality approved and provided at industry leading prices. Besides these, we offer products to the customers in safe packaging to ensure their correct delivery. Located in Secunderabad (Telangana, India), we are supported by large infrastructure which is segregated into various departments. The different units are production, testing, quality control, packaging, warehouse and many more. These units are equipped with latest tools, machinery and others which help us to carry out operations of business effectively. We have hired team members for handling each unit and allotted them task as per their interest.

We also use our customer’s feedback as an opportunity for innovative problem-solving. With the technical guidance of our principals, we will gladly develop with you and for you product variants which correspond with your individual requirements.

Magnetic particle inspection

Magnetic particle inspection is suitable for detecting discontinuities (e.g. cracks) in or near the surface of ferromagnetic materials.

The workpiece must be magnetized in the test area. The discontinuity can be shown best if the magnetic field is vertical to the discontinuity. One possible method for magnetization is using a yoke. The magnetic flux flows into the workpiece through a ferromagnetic yoke. The main field direction is the connection line between the two poles of the yoke. Yokes can be installed in a test bench so that the whole material can be magnetized. If hand yokes are used only the region between the two poles can be magnetized. Multi-directional magnetization can be used to find discontinuities in any direction.

Detection media

There are various types of detection media: a suspension of coloured (including black) or fluorescent particles in a carrier fluid (based on water or oil), or dry powders. Fluorescent media usually gives the highest sensitiviy.

Dry testing:

The test area can be sprayed with a dry magnetic powder, or the workpiece can be dipped into a container in which the particles are kept afloat by air whirling (eddy pot procedure). The dry testing is recommendable where a wetting of the surface must be avoided, or with the examination of hot parts.

Wet testing:

The magnetic powder is suspended in a carrier fluid. The particle size of the powder is smaller so that smaller discontinuities may be detected.

Penetrant testing:

With the Penetrant Testing procedure (also known as DP test or dye penetrant inspection) you can quickly determine surface discontinuities on all iron metals and non-iron metals, some plastics and ceramic materials, glass, etc., provided that the discontinuities are open to the surfaces.

Penetrant testing red

Penetrant testing fluorescent

With the Penetrant Testing procedure (also known as DP test or dye penetrant inspection) you can quickly determine surface discontinuities on all iron metals and non-iron metals, some plastics and ceramic materials, glass, etc., provided that the discontinuities are open to the surfaces.

The liquid penetrant test method is used in the examination of welding seams, cast pieces, in shipbuilding, automobile and aircraft construction, apparatus and tank construction, etc.

Liquid penetrant inspection can be carried out with at daylight visible (red dye penetrant) and/or under UV-light fluorescent penetrants.

The PT method is charactestic for the fact that, contrary to the magnetic particle inspection (MT), defects or discontinuities can be proven also on not magnetizable materials.

Process description

The testing procedure consists of four separate processing steps, for which the following products are necessary:

1. Precleaning (MR® Remover)

2. Application of penetrant (MR® Penetrant)

3. Excess penetrant removal (MR® Remover or water)

4. Application of developer (MR® Developer, white)

For Industrial products contact – sekar.kanniappan@ashrafkuwait.com